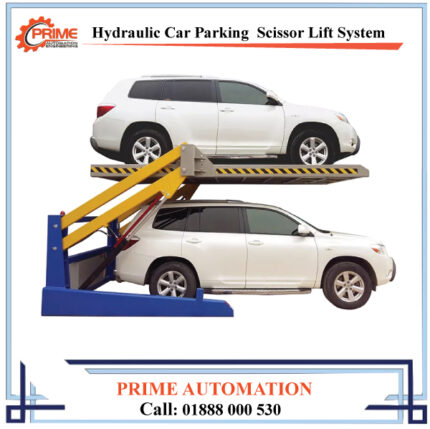

Hydraulic Scissor Lift

The hydraulic scissor lift has applications in many industries, including manufacturing, automotive, aerospace, energy, entertainment, and transportation. It is the most common type of industrial lift, and size and lifting load capacity varies based upon the price and application. If you’re looking to buy hydraulic scissor lift equipment, there are a number of pre-made options available on the market.

For example, the Central hydraulics scissor lift from Harbour Freight is an automotive unit with a broad base of consumers who use it for performing repair work on cars and light trucks in automotive repair shops and home garages. For more specialized applications, you should engage the services of a specialist firm like Handling Specialty to design a unit to your specifications.

Hydraulic scissor lifts are a cost-effective and durable machine that uses an electric motor or other power sources to pressurize hydraulics to lift a payload. It typically consists of a sturdy base, a platform for the load, a configuration of scissor legs, a hydraulic cylinder, and a power source or motor. The “scissor” aspect of the name derives from the fact that there’s a cross-braced mechanism (similar to the arms of a pair of scissors) between the base and the upper platform.

Fixed installation lifts are often used to lift goods between floor levels from vehicles into a building at the goods receiving areas. Mobile hydraulic scissor lifts are typically small, lightweight units that can push goods or heavy objects around a factory or workshop.

Scissor lifts generally have a single-acting hydraulic circuit. The exception to this is where units are very lightweight or require fine position control. A hydraulic control valve is generally employed to raise or lower the lift. This valve is usually operated electrically but can be manual in simple lifts, where the hand-driven mechanism can control the lowering speed.

Several specialized manufacturers produce this type of industrial lift. For example, the Central hydraulics scissor lift is widely used in the automotive repair sector, where it is capable of lifting cars and light trucks.

Therefore, organizations looking to buy hydraulic scissor lift equipment can choose from pre-built units or commission a bespoke design from a specialist manufacturer.

How does a hydraulic scissor lift work? There are a few core components that make up the structure of a hydraulic scissor lift unit. The base at the bottom of the lift offers a stable foundation for the lift during operation. Typically, one to three hydraulic cylinders power the scissor legs to move vertically upwards or downwards. The power source or motor provides the energy for this process. A platform at the top is connected to the scissor legs and carries the load on the unit. The top platform of the scissor lift remains horizontal to the ground as it rises from rest to the raised position ensuring equipment or workers on the lift remain level and balanced as it moves between different heights.

The hydraulic scissor lift working principle relies on the properties and action of hydraulic fluid, which is used to fill the cylinder or cylinders. A system of pushbuttons, levers, and valves directs the circulation of hydraulic fluid. For example, when lowering the scissor legs, a down valve releases the fluid from the cylinder at a controlled rate, closing the legs. Since one end of both the inner and outer legs is connected to the platform and the base, this action causes the platform to lower.

Several manufacturers and hydraulic scissor lift models have designs that address the unique properties of hydraulic fluid under different environmental conditions. For instance, at higher operating temperatures, the fluid becomes thinner or less viscous and can circulate more freely, resulting in a quicker response during lift operations. This situation is reversed at colder operating temperatures, as the hydraulic oil is more viscous.

With fewer moving parts, hydraulic systems nonetheless have the edge over mechanical and electrical systems and provide greater safety and cost-effectiveness. Hydraulic systems also allow a constant torque or force to be maintained, regardless of any changes in speed, making them ideal for uses where accuracy is required when raising or lowering the platform.

A hydraulic scissor lift table is a heavy-duty unit that is designed and constructed for use under the toughest working conditions. They can be employed in loading and unloading heavy objects from trucks. They can also be used in docks and ports.

Hydraulic scissor lift table units can also be used for moving personnel around within their work area, and they can provide a stable platform that allows working on jobs at various heights.

The scissor lift table hydraulic mechanism can typically be raised and lowered repetitively with minimal effort. This permits the loading and unloading of heavy objects to be performed in batches. Hydraulic scissor lift tables can also be specified with conveyor rollers or rotating platforms. Mobile scissor lift tables typically have casters or pivoting rollers to make them movable.

If you’re looking to buy hydraulic scissor lift units for specialist operations, there are almost unlimited options available depending on the specifications needed for your application.

For example, stainless steel lift tables are designed for use in wash-down applications and are primarily employed in the food and pharmaceutical industries, where hygiene or cross-contamination is a concern. A combination of stainless steel, special paints, and other materials is used in their manufacture to deliver corrosion resistance.

Rotating lift tables or “work positioners” are designed for applications where access to all sides of the load is required. Generally, the design also includes a reduced lowered height, which allows for greater access to tall pallet sizes and accommodating greater differences in the operator’s height.

Automatic Gate

Automatic Gate